How To Determine Where (on the Wall) Clad Purlin Clips Will Sit

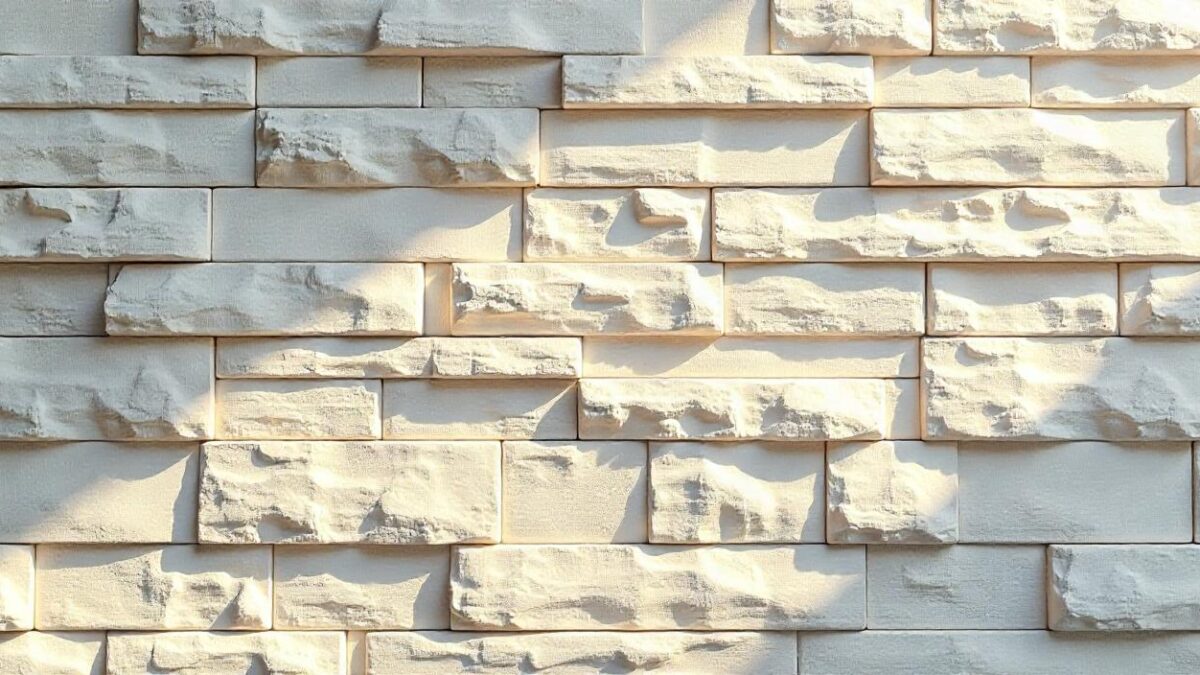

Cladding purlin clips function as essential fittings used in construction to securely fasten a cladding panel to a building's framework. These clips serve a dual purpose: they ensure the Stone Wall Cladding in Udaipur stays in place by offering structural support and maintaining an attractive exterior appearance. Understanding how purlin clips sit on a wall is crucial for ensuring the stability of the construction. Cladding purlin clips are installed in line with the maximum cladding free joint over mild steel insurance, added ceiling void, fall from platforms, and maximum roof lift. This guide explains how to position, install, and benefit from using cladding purlin clips, along with factors to consider during installation.

What Are Purlin Clips?

Before delving into positioning, it’s essential to understand what purlin clips are. Purlin clips are small yet strong components used in metal roofing and wall cladding systems. These clips connect horizontal beams (purlins) to the roof or wall cladding, securely attaching cladding panels or sheets. The clips are designed to hold panels tightly in place while allowing thermal movement, enabling the structure to expand and contract without damage.

Installation of Purlin Clips

Proper positioning of purlin clips on the wall plays a significant role in their installation. Here’s a step-by-step guide:

1. Preparedness of the Wall Surface

Clean and level the wall surface where cladding is to be installed. Any unevenness or debris can compromise the integrity of the installation, leading to misalignment and reduced stability.

2. Positioning of the Purlins

Ensure the building’s structural frame is correctly aligned and secure the purlins. Attach cladding purlin clips to these horizontal beams. The spacing of purlins depends on the building's design and structural requirements. Regular spacing is necessary to distribute the load evenly across the structure.

3. Attaching the Purlin Clips

Fix the purlin clips to the purlins using screws or bolts. Precise placement ensures the clips are positioned at the correct intervals and angles. This arrangement evenly distributes tension on the cladding panels, preventing overloading any section of the wall.

4. Fitting the Cladding Panels

Once the purlin clips are secured, install the cladding panels. The clips clamp the panels tightly against the wall, allowing for thermal expansion and contraction. This prevents buckling or warping, ensuring a smooth and aesthetically pleasing finish.

5. Checking for Alignment

After installation, check the alignment of the cladding panels. Misalignment can affect the structure’s appearance and stability. Ensure no gaps or protrusions are visible. If necessary, reposition the clips slightly to correct alignment issues.

Installation Factors

Several factors must be considered to ensure proper installation of cladding purlin clips:

- Material of the Clips: Choose durable materials like stainless steel or galvanized steel to prevent rust and corrosion.

- Wall Type: The installation method and fasteners depend on the wall type (brick, concrete, or metal frame).

- Thermal Expansion: Allow flexibility for the cladding system to expand and contract with temperature changes.

- Wind Load: In windy areas, secure the clips adequately to withstand strong forces. Use additional fasteners or stronger clips if necessary.

- Maintenance and Accessibility: Ensure the cladding system allows easy access for cleaning, repairs, or replacement.

Conclusion

In summary, cladding purlin clips securely attach cladding panels to a building’s walls, ensuring structural stability and durability. Proper installation, material selection, and consideration of environmental factors result in purlin clips sitting snugly against the wall while offering long-term support. The Stone Evolution is your trusted provider for high-quality cladding systems and expert advice on installation.