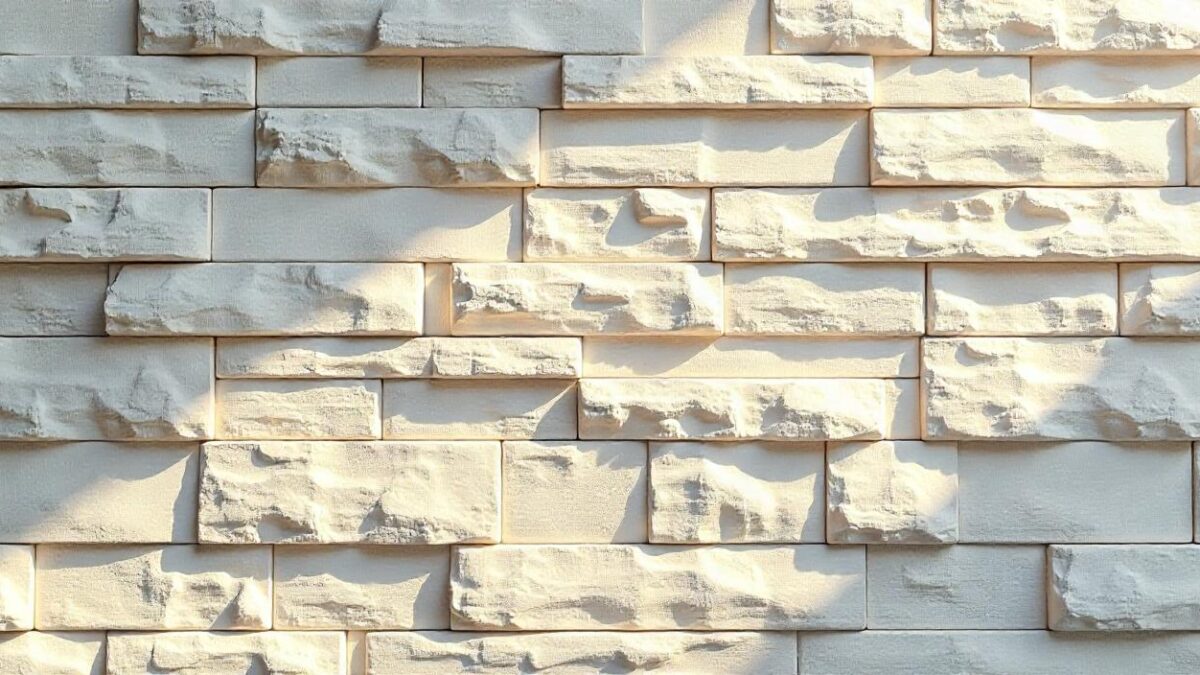

Stone Wall Cladding

Stone wall cladding is a common exterior finish applied to buildings as the cladding helps in providing the building both an aesthetic appeal and also functional protection. This inherently depends on the layer of material that is placed over the structural walls of the building to enhance the insulation along with improving the building’s weather resistance and appearance. Stone wall cladding in Udaipur is important to know how cladding is jointed onto walls so a durable and attractive joint is achieved.

Types of Cladding Materials

There are several cladding options made from different materials endowed with individual advantages. Common types include:

- Vinyl Cladding: Vinyl is resistant to moisture and decay, and thus an outstanding choice for humid climates, and is lightweight and easy to install.

- Wood Cladding: Wood fares well and offers a natural look, but it does need to be kept up, including treated to prevent rot and insect-related damage. Treated wood can make its life last longer.

- Metal Cladding: Metal cladding such as aluminum or steel is very durable, gives a modern look, and is fire, pest, and weather resistant.

- Brick and Stone Cladding: These provide a renewable look and excellent insulation. They are heavy, yet durable and require low maintenance.

- Composite Cladding: Composite cladding is made of a series of materials, allowing each element to retain the benefits of its materials while negating downsides such as maintenance and weight.

Installation Process

The process of cladding installation typically involves several steps:

-

- Preparation of the Wall Surface: Cleans the surface, ensures it is dry and free of mold or mildew, and repairs any damages.

- Framing: Builds a framework made of wood or metal to support the cladding, allowing air circulation behind the cladding to prevent moisture retention.

- Weather Barrier Installation: Protects sheathing or framing with a weather-resistant barrier to keep water out while allowing moisture escape, reducing the chance of rot and mold.

- Cladding Application: Installs cladding from bottom to top, securing it with screws, nails, or adhesives as per the material.

- Joints and Sealing: Prevents water penetration through joints using caulking, flashing, or specialized joint systems.

- Finishing Touches: Adds decorative elements like trim pieces, corner boards, or lighting fixtures to enhance visual appeal.

Types of Common Joints in Cladding

-

-

- Butt Joints: Two pieces of cladding placed next to each other. Easy to install but prone to water penetration if not sealed properly.

- Lap Joints: One piece of cladding overlaps another, offering better protection from water penetration.

- Mitre Joints: Used at corners, these provide a continuous and aesthetically pleasing finish.

- Tongue and Groove Joints: Interlocking cladding pieces create a tight fit and increase structural integrity, commonly used in wood cladding.

-

Maintenance Considerations

To ensure longevity and performance of cladding, regular maintenance is necessary. This includes:

-

-

- Cleaning surfaces to prevent dirt and debris accumulation.

- Repainting or staining wood cladding to prevent rot and maintain appearance.

- Resealing joints and seams as necessary to prevent water infiltration.

-

Understanding how cladding is jointed to walls is crucial for any construction or renovation project. The installation of external wall cladding depends on selecting the right materials, using proper installation techniques, and maintaining the cladding. For high-quality cladding solutions that are durable and aesthetically pleasing, The Stone Evolution can assist you in achieving excellent results.